Research and development unit

With the research and development license from the Ministry of Industry, Mines and Trade, in line with the vision of the company, which is to reach the global markets in the manufacture of lighting equipment, the research and development unit of Meghzazan tries to pass all the required tests by using modern laboratory equipment. based on international standards, the result of which is correct performance, quality assurance and internationalization of the Iranian brand.

Fog Shazazan Molding Unit with expert manpower and using advanced CNC milling machines - CNC lathes - NC sparks - wire-cut - magnetic stone - super drill - radial drill designs and implements all kinds of progressive molds - die cast - extrusion - plastic injection - metal cutting, bending and stretching molds and pressure casting.

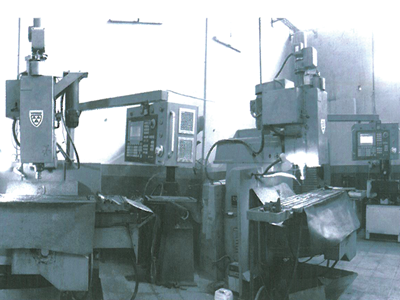

Design unit

The design unit of Mehsazan designs and draws all parts and molds by having expert human resources and using the most advanced software.

Work sheet unit

The fogging sheet work unit includes cutting machines, roll forming, all kinds of welding machines (spot welding, CO2 welding, laser welding, argon welding), multiple hydraulic press machines with a capacity of 60 to 250 tons, laser machines with a power of 1 to 3 kilos. Watt, CNC machines (punch, bend, cut) which are used to make all metal, aluminum, etc. parts.

Plastic injection unit

The plastic injection unit of Mehsazan operates with the necessary knowledge and the use of high-quality raw materials and the use of machines with capacities of 80 to 250 tons to produce the plastic parts needed in the products with suitable quality.

the unit

Fully automatic dyeing and washing

The automatic electrostatic powder paint line is equipped with a robot. By using this method, the thickness of the paint and the temperature of the oven are uniform on the entire surface of the piece, as a result, the resistance of the product against moisture, impact and scratches increases significantly.

The fully automatic washing line equipped with a spraying system performs washing and degreasing of the parts, which maximizes the product's resistance to corrosion and paint adhesion.

Assembly unit

fog makers assembly unit with expert manpower and using modern equipment

Assembles all kinds of lights. Quality control specialist personnel supervise all stages of product assembly to minimize the occurrence of errors in the assembly unit.

Fully automatic SMD assembly unit

This unit designs and produces its product modules by having pick and place machines with a capacity of 1800 parts per hour.

Technical laboratory unit

In the technical laboratory of fog makers, using modern and advanced equipment , electrical , optical, mechanical, chemical tests are performed on the lamp, and the product complies with international standards. The market is offered.

quality control unit

Foggers has a special view on product quality control. Therefore, our experts have all parts and products under strict control in the laboratory and also monitor the production line moment by moment and select some products randomly at the end of the production process and examine them in the laboratory.

Lighting design unit

In the lighting design unit, our engineers use the DIALux software to design the lighting of the esteemed customers of Megzazan, and from the portfolio of Meghzazan products, they suggest the product that is suitable for their space.

Sales and after-sales service unit

Fulfilling the needs of customers, following up on timely delivery of goods, on-site after-sales support and services, and as a result, satisfying the esteemed customers, is the most important responsibility of the employees of the sales department of Mehsazan.